Aero Cruiser Brakes and

Brake Upgrade

By

George Kinnison

At the Vegas Rally, (1994) a number of new members expressed concern

about their brakes. Since these new

members had not attended a "Tech Session" they were

not aware of the brake upgrade I have recommended

for sometime. As we continue to receive new members, this will be

a common subject, so I decided to write a paper for distribution. At the Vegas Rally, (1994) a number of new members expressed concern

about their brakes. Since these new

members had not attended a "Tech Session" they were

not aware of the brake upgrade I have recommended

for sometime. As we continue to receive new members, this will be

a common subject, so I decided to write a paper for distribution.

When Gardner Pacific manufactured the Aero Cruiser they had a

subcontractor provide the fames. From

1988 to mid 1990 the frames were made by Vironex, a California

company. From mid 1990 trough 1992

the frames were made by LGS, an Indiana company. Both companies

obtained the front components from

Chrysler (Chrysler warranty did not go aft of the transmission).

Chrysler identifies these parts as a Dodge

350 one ton (4000 pound axle with 12" disc rotors and

5/8" wheel stud bolts in a 8 bolt pattern).

The differential running gear was provided by Spicer and

manufactured by Dana. Identified as a Spicer

H-60 single wheel application (they did not provide the rear brakes). The Spicer H-60 may also be found

on Ford and GM.

The rear brakes were assembled by the frame manufacturers. They

used a standard Budd brake drum

(3-1/8" X 12") but placed only a 2-1/2" brake

shoe positioned by a 7/8" hydraulic brake cylinder. The hub

was fitted with a 8 bolt pattern using only 1/2" wheel

studs (1/2 ton application).

The result was a hybrid system where the front brakes and back

brakes were mismatched. The

proportioning valve, which was furnished by Chrysler for the

front system, would shift the braking load

from the rear brakes to the front too quickly and the back brakes

did not share the proper work load. This

created excessive use of the front brakes and heated them

excessively which eventually warped the rotors.

Another factor was that rear brake automatic adjusting device

does not work very well due to infrequent

backing up and that allows excessive brake shoe clearance. This

aggravates the situation with little or

minimum rear braking at best. The strange thing about this

hybrid system is that all parts are standard

Chrysler parts. It could easily have been a standard system.

A major improvement can be made to your Aero Cruiser braking

system by upgrading to a standard system.

Have the rear brakes match the front brakes. Since the rear

drums will be removed you can also match the

lug bolts and upgrade the 1/2" studs to 5/8" studs

(your lug wrench would then be the same size).

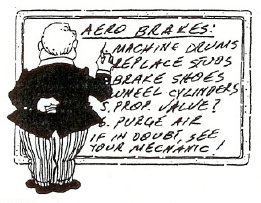

This upgrade consists of the following:

This upgrade consists of the following:

- Remove rear drums and machine out the old 2-1/2" shoe

wear pattern.

- Press out old 1/2" wheel studs, drill out for 5/8"

stud and press new studs in.

Part numbers for 5/8" studs: Dorman -610-20 or NAPA (Balkamp)

641-1297.

Note 1: Don't forget the Lug Nuts. See Lug

Nut Tip for Chrome 5/8-18 RH thread, 7/8, 60 degree nuts for aluminum

wheels.

Note 2: My mechanic says replacing the studs is optional and not really needed.

In fact the 2006 and later Dodge Ram went back to 1/2" nuts and studs except for the

Mega Cab.

Replace 2-1/2" brake shoes with 3" X 12" brake

shoes.

Part numbers: Raybestos 314 (semi-metalic) or NAPA 358R.

Replace 7/8" wheel cylinders with 1 1/8 cylinders.

Part numbers: Raybestos or NAPA 36057 & 36058 (left &

right)

Replace proportioning valve with 1 ton application (if need be)

Part number: Chrysler 4293184

Note 3: I checked with George and he told me that when he upgraded his

brakes he did not replace the proportioning valve at first. After making

several hard stops while test driving, he checked the brakes and found that

the front brakes were much hotter than the rear brakes. He changed the proportioning valve

and test drove it again. This time he was satisfied with the braking front and rear. He told me that our Aero Cruisers have a 3/4 ton

proportioning valve installed in them and it should be replaced with a

1 ton proportioning valve. "They look the same," George said,

"but they aren't".

I checked with the local Chrysler dealer and had them look up the part

number for the proportioning valve used in the 1989 3/4 ton and 1 ton

pickups. They both have the same part number: Chrysler 4293184 which

George says is

the correct one to use. To satisfy my curiosity, we also checked the 1/2

ton pickup and found it uses a different one, the same one used in Dodge

cars.

So do you change it or not? It's list price is $195 but you can normally

get it for $140 to $160 depending on how hard you push the dealer. The

other consideration is the labor costs to change it out and purge the brake

lines again after the initial brake job is done?

My mechanic said it wouldn't make much difference. If we don't change

the proportioning valve, only the rear brakes are involved. If we change

it after, then both the front and rear brakes have to be purged, but that is a

half hour at the most. The cost of swapping the proportioning valve is

the same in any case.

What is a proportioning valve used for? It has 3 basic functions:

- In our rigs it splits the hydraulic pressure 60% to the front

"Disk

brakes" and 40% to the

rear "Drum brakes". Note: The master cylinder has a

part in this also.

- It monitors the hydraulic pressure between the front and rear brake circuits

looking for an imbalance. If an imbalance occurs, the brake light

comes on. This could be because of worn shoes or a loss of hydraulic fluid,

or any number of other reasons.

- It monitors the brake pressure to the rear wheels and relieves

(lowers) the pressure if it gets too high to keep the rear wheels from

locking in a panic stop situation.

For a more detailed explanation do a search for "proportioning valve" on

the Internet. I found several good detailed explanations.

Notes added by Tom Heald

6/09/09

Purge out old hydraulic fluid and fill with new fluid.

These changes will make your Aero Cruiser's brakes the same as the standard Chrysler/Dodge 350 one

ton pickup's braking system. You

will notice considerable reduction in your brake pedal pressure

as well as immediate deceleration as you apply the brakes.

George

Update: Here is a breakdown of the cost for

upgrading the brakes on my 1990 23 foot Rear Bed model in 2009. When

replacing the right rear wheel cylinder with the large 1 1/8" cylinder the mechanic

found the brake line ended up too close to the air bag so he relocated that

brake line. He also remanded that I replace the springs and clips used in

the rear brakes and the rear wheel grease seals for the rear axel, which I

did. I did not replace the proportioning valve or the rear 1/2"

wheel studs which would have added considerably to the total cost.

The List Price in the table below is what you would normally be charged by the mechanic,

the Net Price is the cost if you provide the parts yourself and the mechanic

installs them for you. I found the best overall price at Napa Auto Parts

after shopping around, but that changes all the time. They also charged a

"Core Charge" for the Brake Shoes which I did not include because it

was refunded.

The rear brake shoes were not worn much at all and the wheel drums did not

have to be turned. This is surprising as the coach has 50,000 miles on it!

I guess the front brakes were doing all the work.

I guess the front brakes were doing all the work.

I hope the new brakes take on their fair share (40%) of the load.

They should, with the new 1 1/8 inch Wheel Cylinders and larger 3" Brake Shoes.

I hope the new brakes take on their fair share (40%) of the load.

They should, with the new 1 1/8 inch Wheel Cylinders and larger 3" Brake Shoes.

| Part Number |

Description |

List Price |

Net Price |

| UP-358R |

12" by 3" Brake Shoes (L&R) |

92.93 |

57.32 |

| 36057 |

1 1/8 Wheel Cylinder (R) |

19.27 |

10.50 |

| 36058 |

1 1/8 Wheel Cylinder (L) |

19.27 |

10.50 |

| 2243 |

Maxi Pack (springs & clips, R&L) |

24.06 |

13.29 |

| 475458 |

Rear Wheel Seals for a Dana 60 rear axel (2) |

69.70 |

53.98 |

| DOT-3 |

Brake Fluid (1 Pint) |

|

4.15 |

| 202X3 |

3/16 Flare Union |

|

2.42 |

| 813-1203 |

Brake Line |

|

3.98 |

| Labor |

Remove and replace rear brake shoes, springs and wheel cylinders. Fabricate

new brake line for right rear cylinder, bleed and adjust rear brakes, road

test. |

|

539.00 |

| Tax |

California 9.5% Sales Tax |

|

66.04 |

| Total |

|

|

$761.18 |

Keep on Cruisin', Tom Heald

Do It Yourself:

Here is a step by step for you to upgrade the brakes yourself:

I just did entire rear brake upgrade today! It took 3 ½ hours per

side. This is what I did:

1) Remove the wheel

2) Remove the 8 nuts and pull the hub out.

3) Find the tab that’s keeping the outer hub nut locked and using a

screwdriver and hammer, bend it back out of the way

4) Remove the outer hub nut – this is big – about 2 ½” diameter. It

didn’t require a socket or anything special– on the left side I used a pair

of pump pliers, end-on, coz you can only get the tips of the pliers on the nut

– and with a little force it turned! On the right side it was tighter, so I

used a steel drift and my hammer and gave it a few persuading blows in the

correct direction at one of the points of the nut and it turned – switched to

the pump pliers and it was off easily.

5) Pull out the locking tab washer, revealing the inner nut – same size as the

outer one – mine was easy t turn – on both my both wheels it just took a

little twist with the pump pliers and the inner nut turned.

6) Pull off the brake drum – as you do so expect the wheel bearing to plop out

in a big pool of semi-liquid grease, coz it will, so have a pad of newspaper

down on the ground, between you and the axle and the bearing will drop onto

that.

- By the way – lots of grease is going to appear from this point on. You need

to have a sheet of cardboard or several pages of newspaper laiddown and you’re

going to place the brake drum face-up on that, so that you can see inside the

drum. Grease – lots of it – will ooze out of the hub onto the newspaper.

7) Now clean all the grease of the stub axle and you’ll be looking at nice,

shiny steel.

8) TAKE A PHOTOGRAPH NOW – BEFORE DISASSEMBLING ANYTHING! using your smart

phone or digital camera. That will be VERY handy later, when you're trying to

remember what it all looked like and where everything goes.

9) Now undo the four nuts holding the brake assembly onto the axle –

dead-simple, coz you don’t need to be trying to hold the bolts from behind so

they don't turn because Chrysler sis a neat thing – they gave the bolts a

single flat side back there, so they don't turn while you’re undoing the 4

nuts.

10) Now you can pull the entire brake backplate toward you a couple of inches at

the top– it’s still fully assembled, with brake shoes, springs and all that

stuff – and if you look over the top of it at the brake pipe you’ll see the

brake bleed nipple (3/8” wrench takes that off). Once you have that off you

can get at the brake pipe nut easily and use either a wrench or carefully start

it turning with vise grips, finish off with your 3/8” wrench.

11) Now the entire, fully-assembled brake backplate is almost off – you just

need to unclip the handbrake (foot brake) cable – takes about a inute and

you’ll have the entire thing in your hands

- Total time taken to this point = only 30 minutes, including removing the hub

cap and the wheel.

12) Take the brake assembly over to a convenient table or bench and TAKE ANOTHER

PHOTOGRAPH with your smart phone or digital camera!!

13) Now you can do your brake swap without straining your back having to stoop

down – it's so much simpler and easier. Once you’ve removed the springs –

about 6 of those, and the shoes, you can flip it over and remove the two ½”

bolts and with a little tap, the old slave cylinder pops off.

14) Install your new cylinder and reassemble the whole thing, hang it on the

axle and bleed the brake cylinder right there – dead-easy! Do that before you

bolt it onto the axle, so you can easily reach the bleed nipple.

15) Ok – now bolt it onto the axle with the 4 bolts, hook up the handbrake

cable again.

- By the way – oddly you’re going to find a lot more slack in the handbrake

cable ! These new shoes are set somehow differently, so once you’re all done

upgrading both sides’ rear brakes then you’ll need to take up a whole lot of

slack in the handbrake cable by adjusting it at the front.

16) Now for the brake drum - take a good stiff wire brush and seriously scrub at

the inside of the brake drum. (Make sure you ware a

dust mask to keep the asbestos dust out of your lungs.) – the

inner part where the old, narrow brake shoes didn’t track. On mine I was

REALLY lucky, coz after wire brushing it and then using 300 grit sandpaper on

it, it was nice and smooth and I crossed over that line, a few times with my

finger nail – from the shiny, worn surface to the newly-sanded surface and

back again. There was NO difference in height. In other words my rear brakes

hadn’t worn ANY material off the drum. No wonder the rear brakes on mine

hadn't been doing any work! If you do find a difference in height then

you’ll need to take the drum over to a brake shop and they’ll turn it on a

lathe for you and cut the unused ¾ “ to equal the rest of it - same diameter,

in other words.

IMPORTANT NOTE: between the brake shoe ends, at the bottom is the automatic

brake adjuster. It is a gadget that is a bolt inside a threaded sleeve. Make

sure that when the cable that operates it pulls it, that it does indeed increase

the distance between the shoes. Guess what I found on my rig?!!! – the

left one did indeed tighten the brake adjuster by one click every time I pulled

on the cable – the right one had been installed backwards and every time you

pulled the cable it LOOSENED the brake!!!!!! The shoes on the right side had

virtually NO WEAR as a result!!.

You know how we’re supposed to back up and then jam on the brakes, repeat a

few times and that’s supposed to adjust up our rear brakes? Well that causes a

pull on this steel cable, which makes a little ratchet assembly unscrew the bolt

from its sleeve a bit and that moves the brake shoes apart.

Not in my case – it was doing it the opposite way on my right rear wheel.

Anyway, I hope the above helps you – it’s not hard to do it and I’m so

glad I didn’t entrust a shop to do it – I doubt they would have spotted the

backwards-working brake adjuster and I would have ended up with useless brakes

again after all that work.

Here’s a link for a regular Dana 60 brake overhaul – it describes everything

but he doesn't remove the backplate, which means his version is much harder on

your back and you knees. Also of course he’s not upgrading to wider shoes but

otherwise it's the same.

http://www.boyandjeep.com/tech-articles/ford-dana-60-rear-drums

All the best!

Jeremy MacDonald

Return to the Tip List.

Return to the Tip List.

-- Disclaimer --Information

on this Web Site is provided by members of the "Aero Cruiser Classics" Motor home Club. All

information on this site is contributed by the club members or outside sources and is believed to be reliable; however,

there is no warranty or guarantee that said information or advice is correct or free of defect. It is

offered on a best effort basis and is to be used at your own risk.

|

Copyright© 1999-2016

Freelance Ink.

All Rights Reserved.

|

|

|