!!!

Walter

Return

to the Tip List.

Return

to the Tip List.

Subject:

Engine Maintenance

Tip: If you have not done maintenance in a while,

following is the list of things to check and service

if needed depending on your engine type:

* Air filter for the computer - check for cleanliness

* In-line fuel filter

* Oxygen sensor

* Vacuum lines (especially to MAP sensor

* PCV valve

* Catalytic converter (should be done by a service shop

* Spark plug wires

* Engine timing (for carbureted engines)

Return to the Tip List.

Return to the Tip List.

Subject:

Engine Hoses

Tip:

Check your hoses for deterioration.

Old ones will be brittle and may not hold the pressure.

When replacing them, do not over tighten the clamps.

Return

to the Tip List.

Return

to the Tip List.

Subject:

Fan Belts

Tip:

Inspect on the inner side for cracking

and replace as necessary. General rules of thumb,

if you have not replaced them in the last three

years, take a real close look.

Return

to the Tip List.

Return

to the Tip List.

Subject: Replacement Parts Belts, Hoses,

Filters etc.

Tip:

Since I wasn't able to find specific references to replacement belts, hoses,

etc. I thought I'd post what I've found for my newly acquired 1989 A-C. I

believe that the engine is a 1988 model year based upon the following number:

Chrysler LH 360-88-388 located below the Vironex Chassis VIN.

Dual

Alternator/AC (120amp) belts: NAPA (Gates) 7612

Power Steering/Fan belt: NAPA

(Gates) 7450

Air Pump/Fan belt: NAPA (Gates) 7480

Upper Radiator Hose:

Gates GAT 21406

Lower Radiator Hose: Gates GAT 20046

Replacement Fuel

Pump: Airtex 60519

Air Cleaner Element: Franz CA160

Fuel Filter: FRAM

G3499

I'll post any additional replacement items as I come to

them. jwdub1

Return

to the Tip List.

Return

to the Tip List.

Subject:

Dip Stick

Tip:

Do you have trouble seeing

where the oil is on you dip stick

or better yet, where it should

be? This may help. File a “V”

notch at the upper and lower oil

mark on your dip stick with a

triangular file about 1/16 to 3/32

deep. Clean the dip stick

carefully and put it back. You

may still have trouble seeing

the oil line but you should have

not trouble finding the

reference points.

#212 Petrovich

Return

to the Tip List.

Return

to the Tip List.

Subject:

Engine Oil

Tip:

Recommended viscosity of oil

depends on the temperature where the coach

is being operated. With the mild temperatures

of Southern California, straight SAE 30 weight

is fine, but if you expect a significant change in

temperature, stick with SAE 10W-30 which is

good for temperatures above 0° F. Remember

that certain oil viscosities such as SAE

10W-40 and 10W-50 are NOT recommended

in Dodge engines.

Return

to the Tip List.

Return

to the Tip List.

Subject:

Synthetic Oil vs. Regular Oil

Tip:

It comes down to

personal preference. Some people report engine

running cooler with synthetic oil. If you use regular

oil and you drive in a climate where the temperature

is relatively even, suggestion is that you use a

single grade oil in stead of multigrade due to its

longer life expectancy.

Return

to the Tip List.

Return

to the Tip List.

Subject:

Oil Leaks

Tip 1:

Lon Waterson cautioned about

assuming that your rear main seal is leaking just

because you have an oil leak on the ground. Check the

oil cover first and engine block to intake manifold

interface. That may be the culprit.

Lon Waterson

Tip 2:

Make sure that the screws holding the

valve cover are snug all around. Rear end of the

covers is especially susceptible to oil leaks. Also,

when changing the engine oil, replace the plastic

washer on the oil pan bolt periodically. The gasket

can get compressed to the point where it no longer

does its job.

Return

to the Tip List.

Return

to the Tip List.

Subject:

MAP Sensor

Tip:

If Manifold Absolute Pressure sensor

needs to be replaced, make sure you tell your mechanic

or parts person that the engine is 5.9 liter from a D350

Dodge truck.

Return

to the Tip List.

Return

to the Tip List.

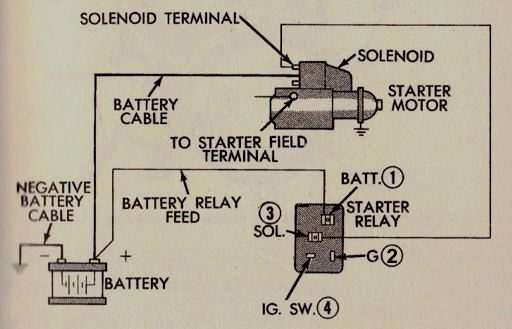

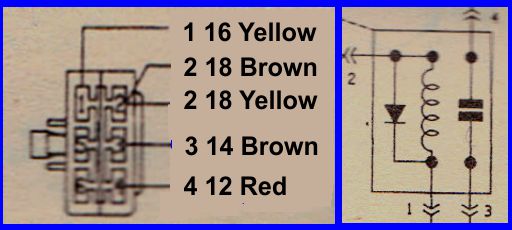

Subject: Relays: Starter, A/C & ASD

Tip:

Automatic Shut Down (ASD) relay failure will stop your engine. It supplies power to the fuel pump, ignition coil,

fuel injectors, and parts of the power module depending on what year your Aero

Cruiser is. The idea is to shut off fuel pressure and the

ignition systems when the key is turned off to prevent fires, dieseling, and other problems.

It is located next to the dashboard

fuse block on the drivers

side and may be interchanged with the Air Conditioning

relay in an emergency even though the one relay has 5

prongs while the other relay has 4.

The starter relay is located under the front hood on the right side. See

"Starter Relay: Trouble Shouting Problems" and "Remote

Starter Switch" for additional information and pictures.

-

A/C Cut Out Relay

12 Volt-30 Amp

Beck Arnley - 203-0012

Fule - Power

(Can also be used for ASD)

-

Starter Relay

AR-201 NAPA Without Bracket

AR-204 NAPA With Bracket

5227300 Mopar

4111971 (hard to read *)

-

ASD - Auto Shut Down Relay

Fuel & Ignition

Mopar - 52331200 (hard to read *)

4443907

From George's Little Black Book

* Note: some of the numbers are hard to read

in George's notes and may not be correct so check them on the relay or a catalog before ordering.

Keep on Cruisin, Tom Heald

Return

to the Tip List.

Return

to the Tip List.

Subject:

Distributor-Cap Fire

Tip:

Beware! If you buy a distributor

cap and rotor, and the rotor is for a bigger shaft, return both, not just the

rotor, even though the distributor cap looks superficially to be the right

size. I learned the hard way. I only bought another rotor the correct size.

It ran fine for the 20-mile test drive up and down a 1000-foot hill, so I

thought all was well. But a few days later we set out for a local beach. We

only got two miles when it backfired a few times and then quit. I pulled over

and saw smoke coming from under the motor cover. I didn't want to remove the

motor cover because it would feed air to the fire, so I tried aiming the fire

extinguisher through the front wheel well at the back top of the motor where I

could see the flames. I was unable to stop the fire that way, so I went back in

and risked taking the cover off. Then I could see that it was the new

distributor cap burring and aim the fire retardant straight into the

distributor. That put the fire out. Praise God, an off-duty fireman had

stopped and came in at that point. He had already called 911 and he spent my

second extinguisher making sure the fire was out. The fire truck arrived a few

minutes later and the CHP a couple minutes after that. Wow, what a

team!

Two hours later the Aero Cruiser was

loaded on a Landoll trailer and hauled to my mechanic's shop. It took me two

days to find and replace all the burnt wires, vacuum hoses, distributor, cap,

rotor, etc. Now I have another few days work to replace the burnt insulation

and clean up the mess. But we thank God we didn't go the way of the Watersons'

fire!

Frank DeRemer

Return

to the Tip List.

Return

to the Tip List.

Subject:

Engine Replacement

|

Tip 1:

In August of 2004, after driving all day with our

“new” Cruiser (we bought a 90/91 model), we

were a quarter mile from home when something

sounded like metal hitting the cooling fan. I stopped

immediately and checked. The fan was just fine. I

then noticed the wing-nut on the air cleaner cover

was going solo. The bolt holding the cover in place

had snapped off and proceeded to find its way

down the carburetor throat into the engine. I guess

the “ s— had hit the fan “ after all.

Fishing around

through the carb. throat with a magnet didn’t

accomplish anything, so after removing the valve

cover and searching further we found damage to

the valves and one piston and cylinder wall. This

engine had been driven 154,000 miles, yet all the

other pistons were still in exceptional condition.

After getting repair estimates, I called George

Kinnison who graciously shared information about

the totally remanufactured engine he had introduced

to our club. Next, through David Cavin at

Chicago Power Systems, Inc., an engine was

shipped to me. After receiving the engine and

inspecting it, Chicago Power accepted my personal

check on George’s word! I have only driven the

Cruiser 350 miles since installation. So far it runs

quietly, smoothly and powerfully.

Here are some stats: LH360 Remanufactured

Chrysler Industrial Stub Engine ass’y w/increased

cooling water pump.

Price $2375.00

Shipping 345.00

Installation with many new parts (hoses, belts etc.)

Approx. $1,700,00

|

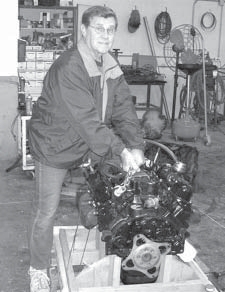

Pete with his new Engine

Pete with his new Engine

Lowering the Engine

Lowering the Engine

Shot from above

Shot from below Shot from below

|

#441 Pete Mondeel

Update:

Pete gave us an update on his engine. He said the engine runs great and he gets about

12.4 MPG on the flat terrain at 55 MPH and 8 to 8.5 on

the hilly terrain.

#441 Pete Mondeel

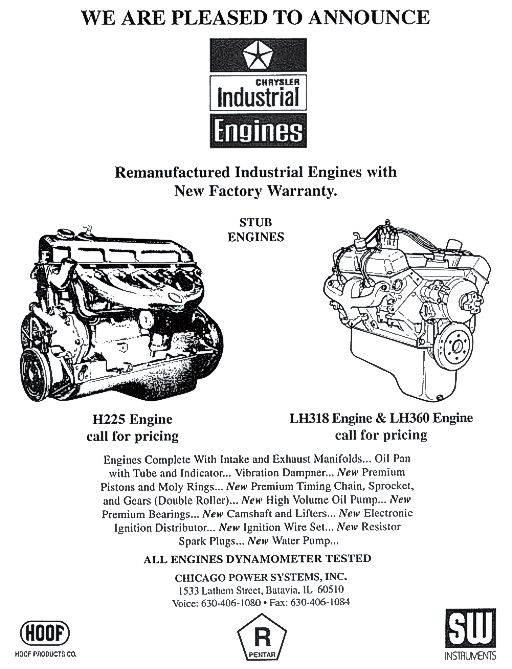

Tip 2:

Some of us have accumulated quite a few

miles on our coaches and though no one knows

how long our engines will last, there is a source

where we can buy remanufactured engines. They

are $2,500 plus $500 for shipping. See below for

additional information.

Removal of the engine should not be difficult. There

is a cross-member bolted to the frame that holds the

transmission and the engine. Once this part is

removed along with two engine mounts, the engine

can be removed from the bottom.

Speaking of engine mounts, they are standard

D350, 1-ton truck mounts and should be checked

periodically for condition and separation. Poor

engine mounts can allow engine to sag or twist

under acceleration.

Return

to the Tip List.

Return

to the Tip List.

Subject:

Alternator Charging System

Tip:

If you should loose your alternator for some reason (it

went bad, belts broke, air conditioner compressor froze,

etc.) keep in mind that you could still drive a long way.

The electrical current needed for your ignition system

will be supplied by your engine battery for a long time

without being recharged. In an emergency, you could

also connect your coach batteries to the engine battery

and have even more current.

#212 Petrovich

Return

to the Tip List.

Return

to the Tip List.

Subject:

Exhaust Manifold Bolts

Tip 1:

Check your exhaust manifold bolts periodically to make

sure they are still there. The manifold is

secured to the block, metal to metal – no gasket,

with a combination of machine screws in some

locations and studs and nuts in other.

These bolts (technically,

machine screws and studs) that hold the exhaust

manifold to the engine head can break off due to

extremes in stress caused by high temperature. Driving

without them for a prolonged period of time can cause

warping of the exhaust manifold and leakage of the

exhaust gases into the engine compartment.

Removing broken studs from the engine head is no easy

task. Common approach is to drill a correct size hole

precisely in the center of the broken stud and clean out

the remaining threads with a tap. Trying to use an

“easyout” (screw extractor) can be a mistake.

Remember that the easyout is smaller than the screw

your are trying to remove and though it is harder it is

also more brittle and can breake inside the hole

creating a bigger problem. Trust me, I’ve been there.

The best thing to do is to take your coach to a

reputable shop capable of performing such a task. If you

insist on doing it yourself, be prepared to eventually

remove the engine head and take it to a shop. On the

plus side, this will give you the opportunity to examine

all components of the engine top side and replace as

needed.

#212 Petrovich

Tip 2:

Bolts and screws that hold

the manifold to the block are grade 5. Suggestion is

to replace them with grade 8 if replacement becomes

necessary. They have been known to brake

from constant expansion and contraction due to

extreme temperatures. Torquing of these fasteners

is also critical since manifold is secured directly to

the block without a gasket between them.

Return

to the Tip List.

Return

to the Tip List.

Subject:

Broken Stud or Machine Screw

Tip:

If you are faced with a situation where you need to

remove a broken stud or a machine screw, consider

using left hand drill bit. You have to drill a hole into the

remainder of the stud anyway, why not use the drill that

works against the threads in stead of with them?

#409 Royston

Return

to the Tip List.

Return

to the Tip List.

Subject:

Starter Overheating

Tip:

Cal Harnetiaux reported a problem with

his starter; it wouldn’t work. He discovered that the

started was “fried” by the exhaust system. It’s a

good idea to inspect your exhaust system to make

sure that there are no sensitive components too

close that could get damaged by the heat. That

would include such things as: control cables,

wiring, brake-lines, etc. If they are too close and

can’t be moved, consider shielding them with heat

resisting materials.

See the tips on: Exhaust System Wrap to cool things down

and

Replacing the Transmission and Throttle Control Cables

at the end of the article.

Return

to the Tip List.

Return

to the Tip List.

Subject:

Starter Problems -- Diesel

Tip: Diesel Starter

Adventure! If you haven't been there already, you will be.

You go to start your Cruiser and all you get is a depressing click. Your first

thought is that the battery must be dead. No, everything was fine a while ago and

everything else is functioning. Great! The starter died.

When the starter

went bad on my 98 Dodge diesel, the dealer told me I needed a new one. $900

later I have learned a few things. I don't know if the gas Aero Cruiser uses the

same starter, but I learned a lot about the diesel. The dealer wants $600 for

the unit itself and about $300 to install.

The Cummins diesel in the

Dodges use a Nippon Denso starter. Most support groups estimate that the starter

itself is good for about 300K miles. What goes bad is the solenoid. The solenoid

itself is as tough as the starter, but the contacts pit and corrode easily and

12volts can't punch through much corrosion.

To cure this problem, Larry

Buck, up in Tacoma, Washington makes a set of oversized contacts and sells the

kit for $35. He also sells the Nippon Denso starter, brand new, with the beefier contacts

installed for about $400.

contact: www.fostertruck.com

The

whole procedure is about 4 hours or less. The toughest part is getting the

starter in and out. All work must be done underneath, so if you have a lift,

great. If not, any blocking or lifting of the front end will help.

As

with any engine work, disconnect the ground wire on the batteries and set it so

it won't swing back and make contact. If you have a disconnect switch, that is

fine too. Crawl underneath and pull back the rubber boot covering the starter

terminal. Disconnect the starter cable. Remember that this is a copper bolt so

it is soft. Disconnect the solenoid trigger wire. If you get your contacts from

Larry, you might want to invest a couple of extra bucks and get his new copper

bolt kit.

The starter is held in with 3ea 10mm bolts. These are $8 ea

from the dealer so try to be nice to them. These are 'star-head' bolts that have

12 points and mate perfectly to a 12pt, 10mm socket. Nothing else will fit. I

tried. An 11mm, 6 pt will fit but slips under torque. I vowed to replace these

bolts with standard hex heads, but I later found that the star heads were

smaller and clearance wouldn't allow hex heads. The bolt between the starter and

the engine wall has very tight clearance and will give you the most trouble. You

will need a 12in extension to get to it. There is not enough swing room to use a

open/box/ratchet end on any of the bolts. Loosen the top bolt first but leave it

installed. It is the easiest to get to (you can't see it but it is easy to feel

for). It will hold the weight of the starter while you remove the difficult

lower two bolts. Then, holding the weight of the starter with one hand, back out

the top bolt. There are no gaskets involved.

Once you have the starter

on the bench, the rebuild is quick and easy. It just depends on how much time

you want to spend cleaning things. Should take about 20 min. Larry includes good

instructions with the kit. You don't need to open the starter, just the 3 screws

on the solenoid end cap. The contacts are right there. When reassembling,

remember: The bolts are copper and strip easily. Tighten firmly, but don't crank

down.

If you are adventurous, you can bench test the starter. Using

jumper cables, hook it up. Nothing will happen until you trigger the solenoid.

Using a short hunk of 16awg or larger wire, and holding the starter FIRMLY (It's

a torquey little dude), short the positive post to the trigger post. Stay away

from the gear end and try to touch the nuts on the posts. Touching the treads

might arc and mess them up. Just a touch will do. Don't hold it there. If

changing the contacts fixed the problem, you will know.

Putting the

starter back in is an exercise in frustration. That inner bolt is a bear to line

up. Put the top bolt in first and hand insert it but don't seat or tighten. This

will hold the weight but allow the starter to wobble a bit and give you some

play room to get the other 2 gremlins in. This could take the remainder of the

day.

Put the electrics back in in reverse order and you are up. Watch out

for over tightening that copper bolt. This fix is waaay cheaper than

$900.

-=Dale=-

Return

to the Tip List.

Return

to the Tip List.

Subject: Starter not working. It just clicks!

Question: We

just returned from a trip a while back and are getting ready for another when I

tried to start Aero Cruiser. The ignition switch just clicks the starter. New starter was installed two years ago.

Just read your article on starter by-pass switch. Not sure I can find those

cables/ wires. Any advice? Give us a call.

Marvin & CeCe

Answer: If

it is clicking then the starter by-pass switch will not help. It is used to

bypass the the starter relay to pick the

solenoid on the starter. The clicking you hear is the starter relay or the

solenoid on the starter. It is either your battery being low (most common) or it

is the starter. It may just be the contacts that run the starter motor, the

motor itself or the Bendix gear. There are several tips on the starter motor and heat related

problems from the exhaust. See --

tip-run01.htm#t2002-03-08

& tip-run01.htm#t2009-07-08 --

which is for diesels but it is a good description of starter problems.

To

shoot the bug; crawl under and check the voltage at the Starter motor. If it drops quite a

bit when you try to start the engine then it is probably your battery. If you hear or see

the Solenoid click but not engage then the problem is probably in the starter

motor: either a bad motor or the contacts that cause it to spin. If you

hear the starter spinning but not engaging then it is probably the Bendix gear

that engages with the flywheel to turn the engine over.

If you can't shoot the bug yourself take it to a good mechanic who will

actually look at the starter before replacing it. In any case consider --

tip-ext05.htm#exhaust-w -- "Exhaust System

Wrap" to cool things down and protect the starter and cables.

Keep on Cruisin', Tom Heald

Return

to the Tip List.

Return

to the Tip List.

Subject: Starter not working. It won't even click!

Question:

Can't start, no crank, nothing... Check and charged batteries, still

nothing. Well I read all the tip sheets about the starter problems,

with overheating and such. I was able to jump the ignition wire to

starter hot cable. And was able to start the coach that way. So I know

the start works now. I think the connections to the starter are a bit

corroded and my next step is to disconnect and clean up wiring and retest.

"Metro"

Answer:

Possible problems are: the starter relay (up front under the hood on the right

side) and the Transmission interlock switch in the starter circuit (found on the

transmission so you can't start it in gear).

See -- Starter Relay: Trouble Shouting Problems -- and

http://aero-cruiser.fl-ink.com/tip-run04-a01.htm

-- for more information and a typical wiring diagram. There is also a "fusible link"

in the circuit as can be seen in the wiring diagram. It looks like any other wire,

except it is designed to melt with high current. If it has melted, you won't start.

It sounds like you tried all of the other common problems found in tip -- http://aero-cruiser.fl-ink.com/tip-run01.htm#t2009-1-22 -- but review it to

make sure. Let us know what you find.

Keep on Cruisin', Tom Heald

Return

to the Tip List.

Return

to the Tip List.

Subject:

Starter Relay: Trouble Shouting Problems

Tip:

When you try to start the rig and all you get is that sick feeling in your gut; you know you are in trouble. So what do you

do?

When you turn the key to the Ignition position you should see the lights in the dashboard display come on for a short while to test them out.

If not then you most likely have a dead battery or the Ignition circuit or switch is bad or power to it is missing.

The easiest place to test power from the Ignition switch is in the "Coach Electrical

Box". The Ignition relay should pick and provide 12V power to the ignition terminal strip. Generally you will hear the "Air Compressor" running as soon as you turn the Ignition switch to the run position.

When you turn the key to the Start position and it just clicks, then go to the

"Starter not working. It just clicks!" tip.

If nothing happens then go to the "Starter not working. It won't even

click!" Tip.

If you think it might be the "Starter Relay"; you can check it out as follows;

however, it's hard to get a jumper or meter probe on the contacts without

installing test points in the starter relay wiring.

- Using a Volt meter you should see 12 Volts at terminal 1 (yellow 16 gage

wire) from the Battery

or the Ignition

switch in the Run position depending on the year.

- At terminal 4 (red 12 gage wire) you should see 12 Volts when the Ignition is turned to the start position.

- At terminal 3 (brown 14 gage wire) the Solenoid line will have 12 volts when the relay picks.

- Terminal 2 (brown & yellow 18 gage wirers) provides ground to the circuit through the "Transmission interlock switch" found in the transmission. If you don't have a good ground then the shift linkage or the interlock switch is out of

adjustment or bad. It should provide ground when the transmission is in park.

With the ignition switch in the run position test the Starter Relay by

installing a heavy duty jumper from (1) to (4). Note: this bypasses the ignition

start switch. If it cranks then the relay is ok.

If not then install another heavy duty jumper from (2) to ground. If it cranks then the relay is ok and the "Transmission interlock switch" is bad or out of adjustment. If not then the relay is bad and you need to replace it. See

"Relays: Starter, A/C & ASD" for addition information and tips.

You can bypass the relay and start your rig by using a jumper from (4) to (3) to pick the Solenoid on the

Starter. This is what the "Remote Starter Switch / Transmission Interlock Bypass

Switch" does as described in the tip.

Keep on Cruisin' -- Tom Heald

Return

to the Tip List.

Return

to the Tip List.

|

Copyright© 1999-2016

Freelance Ink.

All Rights Reserved.

|

|