|

Under the Coach or in the Compartments: holding tanks and valves,

water pump (even if inside), water tank and external supply systems, spare tire, door step, gas

tank & sensor, exhaust system, the battery compartment, batteries and battery isolator, 110 volt docking cord, 110 volt generator and compartment and the access panels for the refrigerator,

hot water heater and forced hot air heater.

Click on the

to

go to its Tip: to

go to its Tip: |

|

Holding Tank Gate Valves

|

|

Dragging or Replacing the Holding Tank Valves

|

|

Awkward Holding Tank Dump Valves

|

|

Electric Step not retracting and how it works

|

|

Electric Step Fuse

|

|

Electric Step Models

|

|

Electric Step Switch and Parts

|

|

Power Step Joints

|

|

How to Manually Retract the Step

|

|

Replacement Step

|

|

What is the best House Battery solution: 6 or 12 volt, 1 or 2 batteries?

|

|

Batteries -- Need wiring diagram.

|

|

Battery Isolator, Troubleshooting and Replacement.

|

|

Sliding Tray for Golf-Cart Batteries

|

|

External 110 Power Reverse Polarity

|

|

Pig Tail 50 AMP to 30 AMP

|

|

Voltage Booster for Low Campground 110 Voltage

|

|

Leveling Jacks - HWH Hydraulic

|

|

Leveling Jacks - A&E Electric

|

|

Hanging Wires

|

|

Gas Tank, Fuel Gauge Sensor & Fuel Pump

|

|

Gas Gage Accuracy (off Page link)

|

|

Fuel Tank Capacity

|

|

Gas Tank and Gas lines

|

|

Gas Tank Filler Neck

|

|

Exhaust System Wrap to cool things down

|

|

Exhaust System Replacement

|

|

Catalytic Converter

|

|

Generator Over-Voltage

|

|

Generator Fuel Line

|

|

Generac Generator

|

|

Honda Generator Won't Start

|

|

Honda Generator Removal for service

|

|

Water Heater Gas Burner & Replacement

|

|

Refrigerator Gas Burner

|

|

Keeping Gas Burners Clean and Bug free

|

|

Flat Tire? Use the Air Bag Compressor to fill it up. (off page link)

|

|

Flat Tire - How to change it

|

|

Spare Tire - Lowering and Raising

|

|

Fresh-Water Gauge

|

|

Water Pump Replacement 1

|

|

Water Pump Replacement 2

|

|

Recycling Grey Water

|

|

Running Gear Tips: Front & Rear Suspension, Wheels, Tires, Brakes etc. (off page link) |

-- Disclaimer --Information

on this Web Site is provided by members of the "Aero Cruiser Classics" Motor home Club. All

information on this site is contributed by the club members or outside sources and is believed to be reliable; however,

there is no warranty or guarantee that said information or advice is correct or free of defect. It is

offered on a best effort basis and is to be used at your own risk.

Tips:

Subject:

Holding Tank Gate Valves

Tip:

If you have a difficulty

opening and closing the gate valve, lubricate

the shaft with WD-40 oil and work it in-and-out.

If that doesn’t solve the problem, replace the seals

but make sure you buy the correct manufacturer

and size seals from any RV store.

Update:

The valves are quite inexpensive. I recommend replacing the whole valve instead of just the seals.

It's actually faster and easer to replace the complete valve that to rebuild the

old one assuming you can find all the parts.

Keep on Cruisin' -- Tom Heald

Return

to the Tip List. Return

to the Tip List.

Subject:

Dragging or Replacing the Holding Tank Valves

Question:

The Holding Tank Valve is very low and I am afraid I may bump it when I am on

the road.

Answer:

A number of Aero Cruiser owners have reworked their gray/black water

dump valve and managed to raise it a few inches. They differ from

coach to coach, so its a matter of looking at it and figuring out how

to save some space. I whacked mine once backing into a campsite on

the Blue Ridge Parkway. Answer:

A number of Aero Cruiser owners have reworked their gray/black water

dump valve and managed to raise it a few inches. They differ from

coach to coach, so its a matter of looking at it and figuring out how

to save some space. I whacked mine once backing into a campsite on

the Blue Ridge Parkway.  What a pain. I just

"Rube Goldberged" it together on the road with epoxy and didn't

raise it any at the time. Some years later I had to rebuild it and I managed to

raise it about an inch. What a pain. I just

"Rube Goldberged" it together on the road with epoxy and didn't

raise it any at the time. Some years later I had to rebuild it and I managed to

raise it about an inch.

The black ASB pipes, "Y" connector, elbow and ASB Cement are all standard plumbing items you can get at any

good hardware store. When I assembled mine I trimmed the connectors down as much

as I could to give me more ground clearance.

The holding tank valves and the adapters to the pipes and

fittings are also a standard part you

can pick up at any good RV Shop.

When I replaced the two valves in my rig, the new ones came with plated steel

bolts and nuts. The old ones had brass bolts and nuts which were, much to

my surprise, not corroded at all.  They were easy to remove, so I used the same brass bolts and nuts to reassemble

everything.

They were easy to remove, so I used the same brass bolts and nuts to reassemble

everything.

Keep on Cruisin' -- Tom Heald

Return to the Tip List. Return to the Tip List.

Subject:

Awkward Holding Tank Dump Valves

Tip:

Some coaches have

their dump valves installed in such a way that

requires acrobatics to operate. Bruce suggested

installation of solenoid operated valves available

at RV stores for easy remote operation.

Return

to the Tip List. Return

to the Tip List.

Subject:

Electric Step not retracting and how it works

Tip 1:

The first thing to try is the "Step" switch on the instrument panel to the left of the

searing wheel. It controls whether the

(1) step opens and closes every time the side door is opened and closed or

(2) weather the step stays down until the rig is started with the side door closed.

Start your rig, close the side door and see if changing the switch makes any difference.

Keep on Cruisin', Tom Heald

Tip 2:

Don't know if you step is up? Ken installed a NAPA

door jamb switch (DJ6300) on the rear of the coach

step bracket and a VDO green warning light (600 845)

on the dash. If the step does not retract and open the

switch, then the green light is on when he starts the

Engine.

#215 Stahl Update:

Sometimes the coach step would not retract and

sometimes, it would not extend. The door jamb switch

which controls the step, located on the right side of the

door jamb, near the bottom was in contact at the back

of the switch on the frame. With the switch making

contact, the step control thought the door was still

open. So, Ken installed some insulation around the

back of the switch. So far, the step is working.

#215 Stahl

Return to the Tip List. Return to the Tip List.

Subject:

Electric Step Fuse

Tip:

The electric step is controlled by a 5 amp fuse. It the fuse

burns, replace with the same rating. Do not install higher

rated fuse.

Return

to the Tip List. Return

to the Tip List.

Subject:

Electric Step Models

Tip:

At the last rally we discovered the Aero Cruisers have

three different models of Electric Steps. They all have

different mechanical parts and control boxes. Quick

reference is to check color of the control box.

white, blue, or orange. Big help when looking for replacement

Parts!

#102 Kinnison

Return to the Tip List. Return to the Tip List.

Subject: Electric Step Switch and Parts

Question:

Well, I've tried 2 supply stores looking for a replacement switch for my

electric step. Trouble is knowing what the heck to ask

for. I've not been successful in trying, even asking for info on the

"kwickee" step. Maybe you know how to get to the right place??? --Tom

Answer:

This may be your switch, as I have this kind: http://www.kwikee.com/Images/905307.jpg

Here

are all their switches: http://www.kwikee.com/Aparts_steps.html#switch

Note

that that is at www.kwickee.com. You can

click on each switch to see the picture. Beware that some of those switches are

closed unless activated (by the matching magnet) and others are open until

activated. You must get the right one. Best is to report to them the color of

the control box and that it is a 1989-or-so vintage, so you get the right

one. Probably won't cost much even from Kwickee.

--Frank

Update:

Just wanted to let you know that my switch is different. I found the switch

I need after much

sweating over the computer. It's a Honeywell micro switch which is

no longer manufactured and no replacement is made. All distributors

are out of them except "Electrol" which has 48 of 'em on their shelf

and they are $75.00 each. Ain't that a good 'un?? The supplier is "www.electrolsupply.com", and the phone# is (800)663-6576.

Tom Even

Return

to the Tip List. Return

to the Tip List.

Subject:

Power Step Joints

Tip:

Make sure you lubricate the Power Step

joints routinely to keep it moving free.

Return

to the Tip List. Return

to the Tip List.

Subject:

How to Manually Retract the Step

Tip:

The first thing to do is to check for a blown fuse and then try the switch in different

positions as explained in the tip above. In the short

run to get the steps back in, you can remove the cotter pin then knock out the

pin that connects the gear box to the lever on the step unit and tie the step

up. From there you would need to troubleshoot to determine if the problem is

electrical or mechanical. When my steps did this, I found the motor to be the

problem. I took it apart, polished the armature and cleaned the gaps between the

copper bars. When I put it back together I had to reset the armature end play

using the allen head set screw.

Good Luck!!!

Walter

Return

to the Tip List. Return

to the Tip List.

Subject:

Replacement Step

Tip:

If you have the original that came with the A-C and it stoped working, it may have finally died. The

ones produced the late 80s - early 90s were a little anemic. Kwikee Step in

Oregon has a rebuild kit with a better, more robust motor and new

electronics. But for about $20 more, you can get a new unit out of Camping

World.

-=Dale=-

Return

to the Tip List. Return

to the Tip List.

Subject:

What is the best House Battery solution: 6 or 12 volt, 1 or 2 batteries?

Question:

A friend of mine said to replace my 2 bad house batteries with two 6 volt rather

then two 12 volt. Said the amp hours are longer. Anyone else done this?

Answer:

Using two 6 volt Deep-Cycle batteries hooked up in series is a good solution; but it

tends to be a bit expensive. There is a common misconception that two 6-volt 200 amp-hour

batteries used in series will double the amp-hours available. This is not true. It will

double the available power (watts) but not the amps.

Remember back in your high-school science

class the formula W = V*A? That's Watts = Volts * Amps. One 6-volt battery times 200

amp-hour = 1200 watt-hours, times 2 batteries = 2400 watt-hours. One 12-volt, 200 amp-hour

battery = 2400 watt-hours. Each setup will deliver the same amp-hours and wattage given the

stated ratings.

Using two 12 volt Deep-Cycle batteries hooked up in parallel will also work as long as the batteries

remain a matched pair. In this case you will get the total amp-hours of both batteries. For example:

12 volts times 130 amp-hours = 1560 times 2 = 3120 watt-hours. The problem is that

as they grow older and one battery becomes slightly weaker, it will draw down the other battery even with no external load from the camper. This

constant load will cause one or both to fail much faster than they might under a normal load. A

standard battery

isolator won't solve the problem because both batteries share the same load.

You could design one, but I don't think it is worth the effort.

So, contrary to the myth, two 12 volt, 130 amp-hour batteries will deliver more power than two 6 volt, 200

amp-hour batteries. A "good" salesman may tell you that's a load

of bologna; however, any

"honest" salesman will

tell you it's true.

My preference is to install the largest 12 volt Deep-Cycle battery I can

find. One with the most amp-hours,

that will fit in the available space. It will cost less than either of the other solutions,

deliver about the same power and almost certainly last longer than two 12 volt

batteries in parallel; probably 2 to 3 times longer.

Number and Type of

Deep-Cycle Batteries Used |

Amp Hours

at 12 Volts |

Watt Hours |

Approximate Cost |

| 2 - 6 volt 200 amp hour Batteries |

200 |

2400 |

$200 |

| 2 - 12 volt 130 amp hour Batteries |

260 |

3120 |

$150 |

| 1 - 12 volt 210 amp hour Battery |

210 |

2520 |

$90 |

My personal experience: When I purchased my 1990 Aero Cruiser in

1996 it had two 12 volt coach batteries, both dead. When I removed,

charged and tested them, one was good and one bad. I replace the bad one

and one year later they were both bad.

Almost the whole time they were

sitting in the driveway with the charger on, which was a mistake. I unplug

the coach and put it on a timer so it only run the charger for an hour a day and

then I replaced the house batteries with two identical 130 amp-hours (if memory

serves) 12 volt Deep-Cycle batteries.

They lasted 3 years which is the low end of a batteries 3 to 5 year life expectancy.

Not happy, I checked around for two 6 volt Deep-Cycle batteries. I found a

pair of 200 amp-hour batteries for about $100 each if I remember

correctly. While talking to various sales people I received both stories

on the amp-hours, so I did the math myself and went out and bought one large 12 volt Deep-Cycle

210 amp-hour battery for under $90 that takes up the same space as the 2 smaller

12 volters. That was back in 2003 and it is still working in 2011.

So what is the difference between a "Good" salesman and an "Honest"

one? Well, it's all in the eyes of the beholder! After all, the "Good"

salesman is always beholding to the sales manager!

Keep on Cruisin', Tom Heald

Update:

In my 1990 23' rear bath model with the slide out battery compartment to the

right of the main entrance door, I use a 12 Volt Group 24 (11" Length x 6

3/4" width x 9 1/2" height) for the truck battery and a 12V Group 29M

(13" Length x 6 3/4" width x 9 1/2" height) for the coach battery

both running lengthwise with a 13" 4x4 and some thin shims to fill the

4" gap between them so they won't move around.

As an alternative there is room for 2 Group 24M batteries length wise next to

the single Group 24 truck battery taking up all of the remaining room. They can

be 2 - 6 volt batteries in series or 2 - 12 volt batteries in parallel.

The pros & cons of each of the three options are explained above.

Keep on Cruisin', Tom Heald

Return to the Tip List. Return to the Tip List.

Subject: Batteries -- Need wiring diagram.

Question: Hi, I'm in need of

a wiring diagram for my 23' Cruiser. Some how before I got it the cables to the

batteries were replaced and I don't think that they put back were in the right

order. I have to use BATT Boost every time to start the engine, or generator.

Thanks for any help you can give me. Tim Meyer

Answer: It's pretty straight forward.

Each of the batteries go to a CB (a round self resetting circuit breaker) then the

Battery isolator and the two large relays in the Coach Electrical Box (the

Ignition and Crossover relays) found in one of three places:

* the Front Compartment under the Hood or

* inside the cabinet under the Refrigerator or

* under the interior front Step.

The first thing to check is if all the batteries are charging correctly.

If yes, then you can assume that everything from the

Battery isolator to the batteries is ok and look on the other half of the circuit

for the problem. You can trace

all of it out with a meter by following the wires under the coach and look for a

loose or dirty connection along the way. Go here for the wiring

diagram of the Coach and Truck Batteries.

Keep on Cruisin' -- Tom Heald

Return

to the Tip List. Return

to the Tip List.

Subject:

Battery Isolator, Troubleshooting and Replacement.

Tip:

My batteries were dead and I had an appointment to get it serviced. Bummer! To troubleshoot the problem I grabbed my voltage meter

and crawled under my rig beneath the passenger compartment. Tip:

My batteries were dead and I had an appointment to get it serviced. Bummer! To troubleshoot the problem I grabbed my voltage meter

and crawled under my rig beneath the passenger compartment.

With the engine running and no AC power to the coach, I checked the voltage and had 14+ volts coming into the

center post of the

Battery Isolator; however, the battery side showed low voltages -- 10 or so volts indicating

a dead battery. I charged the batteries and they held there charge.

I drove it around and then checked again. Everything worked ok and did no

give me any more problems and when I checked it later with the engine running, I had 14+ volts on the

center post coming from the alternator and 14- volts

on the

battery sides. Just as it should be when charging.

Note: The red wire seen in the pictures

is an add-on. It goes to a post I added under the front hood so I

can hook my generator's battery charger up to the house battery

there. The Battery Isolator consists of two diodes inside a sealed unit.

Its job is to allow current to flow from the alternator to each battery while stopping

any

flow between the House Battery and the Truck Battery circuits. It is a solid-state

device. There

is nothing to stick and there is no ground to the Isolator except at the batteries. My conclusion. There must have a been a bad connection

inside the

Battery Isolator which is a solid-state unit sealed with epoxy. Just to be on the safe

side, I ordered a new unit -- NOCO

IGD140HP Grey 140 Amp High-Performance Battery Isolator for $35.34 on Amazon in

2012.  I had no more problems over the next

several months. It was some time before I decided to install the new Battery Isolator. The new

unit has an extra post that is not used on the Aero Cruiser it is for some

alternators found on more resent trucks. The unit is larger than the old one but

fit into the same location. The only problem, the connecting posts were

larger so I had to drill out the connectors to fit. I should have clamped

the connector to a backing board when drilling so the drill wouldn't catch and twist

off the connector. I didn't and had to replace one connector. I believe

the larger posts are required by law on newer units. The

older 120 amp Sure Power 1202 Battery Isolator I replaced had

smaller connecting posts. It is still available online though

it is a bit more expensive and is prone to this problem. I had no more problems over the next

several months. It was some time before I decided to install the new Battery Isolator. The new

unit has an extra post that is not used on the Aero Cruiser it is for some

alternators found on more resent trucks. The unit is larger than the old one but

fit into the same location. The only problem, the connecting posts were

larger so I had to drill out the connectors to fit. I should have clamped

the connector to a backing board when drilling so the drill wouldn't catch and twist

off the connector. I didn't and had to replace one connector. I believe

the larger posts are required by law on newer units. The

older 120 amp Sure Power 1202 Battery Isolator I replaced had

smaller connecting posts. It is still available online though

it is a bit more expensive and is prone to this problem.

Keep on cruisin', Tom Heald

Return

to the Tip List. Return

to the Tip List.

Subject:

Sliding Tray for Golf-Cart Batteries

Tip:

My Cruiser was modified by the prior owner. He moved the 12v engine battery

elsewhere and put two 6v golf-cart batteries in the original compartment just

in front of the entry door, under the third chair, to supply coach power. He

made a non-sliding box to hold those two (taller) batteries. It was a pain to

get water into the batteries. I found on eBay a sliding tray made by Kwikee:

product #905700010, which is shown in the first picture, along with a pair of

aluminum channel supports, a thin floor, and two strong side supports. Tip:

My Cruiser was modified by the prior owner. He moved the 12v engine battery

elsewhere and put two 6v golf-cart batteries in the original compartment just

in front of the entry door, under the third chair, to supply coach power. He

made a non-sliding box to hold those two (taller) batteries. It was a pain to

get water into the batteries. I found on eBay a sliding tray made by Kwikee:

product #905700010, which is shown in the first picture, along with a pair of

aluminum channel supports, a thin floor, and two strong side supports.

The

space I had to work with is shown in the next photo to the right, with the support box installed.

Then with the tray

extended: I had to trim the fiberglass below about 1/8th inch to get enough

depth for these tall batteries: Then with the tray

extended: I had to trim the fiberglass below about 1/8th inch to get enough

depth for these tall batteries:

And

finally, box painted black, permanently installed, and loaded with the batteries: And

finally, box painted black, permanently installed, and loaded with the batteries:

Not a bad solution. Now I will be more faithful at adding water!

P.S. Because the golf-cart batteries are so tall, I had to trim the lower

fiberglass about 1/8 inch to allow the tray to come out. That also means I have

to remove the door and its frame (four screws) to slide the batteries out, as

shown. This tray would also work for the original (shorter, 12v) batteries, but

the floor would not have to be so deep and there might be enough room for the

tray to come out without having to remove the door. Someone else will have to

try that.

--Frank DeRemer Update:

The original plastic, sliding battery tray in my 1990 Aero Cruiser measures

14" deep, 18" wide and provides 10 inches of clearance for standard

sized batteries. Franks tray is 13 3/4" wide x 13" deep and

can accommodate batteries that are 11" tall.

Keep on Cruisin', Tom Heald

Return

to the Tip List. Return

to the Tip List.

Subject:

External 110 Power Reverse Polarity

Tip:

Although shock from the improperly wired

receptacle itself is not likely, it can be

dangerous for an RV connected to a power

source with reverse polarity. If the power source

is not correctly wired, your RV itself can become

“hot”, which means you could become a

conductor if you were to touch your coach while

walking around the outside. Obviously this could

cause serious injury or even death under certain

circumstances.

Another risk is that the safety mechanism on

an electrical device connected to a reverse

polarity source of power may not kick in, which

could cause serious injury. For example, a

power tool may start automatically as soon as

it’s plugged into the improperly wired receptacle

or it may not shut off when you try turning it off.

Before you hook up to any unknown power

source, you should use a circuit tester to check

for correct wiring. Plug the tester into all the

receptacles – both top and bottom – for an

accurate reading. You should always test the

outlet before hooking up, but if you’ve already

plugged in, unplug your RV and don’t use the

outlet until it’s repaired. Make sure to report the

problem to the campground owner at once.

Good Sam

Return

to the Tip List. Return

to the Tip List.

Subject:

Pig Tail 50 AMP to 30 AMP

Tip:

When traveling in

summer time, you may come to a park with inadequate

30 AMP service if everyone has their air

conditioning on. It is suggested you get a 50 to 30

AMP pigtail so you can actually use the park’s 50-

amp circuit, which is less likely to be overloaded.

dragi

Return

to the Tip List. Return

to the Tip List.

Subject:

Voltage Booster for Low Campground 110 Voltage

Answer:

Elizabeth writes: I met Frank Izbinski who lives in

my town and thought he had an interesting

product, Voltage Booster for RV’s. Toll Free 888-

624-3347. He will be selling at his booth at the

Quartzsite swap meet. Since I don’t know anything

about this stuff I thought I would pass the

information along for you guys to check out.

www.voltagebooster.com

#139 Haynes

Return

to the Tip List. Return

to the Tip List.

Subject:

Leveling Jacks - HWH Hydraulic

Tip 1:

Ken had a spring break on one of the HWH Hydraulic

Leveling Kickdown Jacks, 110 Series.

He went to www.hwhcorp.com, then technical

information, repair parts manual, jacks, kick-down and

finally AP7129. The replacement is R6824 spring kit

1.5” x 10”. The kit contains two springs and retaining

pin. The cost was $12.21, plus shipping of $4.90.

Installation is relatively easy. The replacement springs

are 1'’ shorter, so requires some muscle.

In the retracted position, pull pin and remove springs.

First, need to twist the spring to break the paint. Install

the two new springs and pin. Using some nylon line and

a “loggers hitch knot” with one end to the spring and the

other to the coach frame, he pulled the spring into

place and slipped the spring end into the hole on the

foot. Slick!

#215 Stahl

Tip 2:

Rick bought spring replacements from HWH

(#R6824 Spring Kit 1.5” X 10”) for his leveling jacks. Cost

$12.00 per pair plus shipping.

Ken Stahl wrote in a tech tip back in 2003 (Report

#034, Nov 2003, page 14), how to change the springs.

His technique for stretching the springs to snap onto the

jack’s foot required the knowledge of tying a lumberman’s

knot or something like that. Anytime Rick hears

of a complicated knot he just adds three or four more

granny knots!

The job turned out very easy (even for him!). He got

a ratchet tie down strap, tied one end around a stationary

part of ole’ Aero then made a 6” loop of nylon line

hooked to the spring and the hook of the ratchet tie

down. After tightening the ratchet to stretch the spring

opposite the slot on the jack’s foot, he twisted the open

end of the spring into the slot then took a knife and cut

the nylon loop with the springs snapping into place.

Make another nylon loop and repeat. Worked

slicker than snot.

#101 Krafft

Return

to the Tip List. Return

to the Tip List.

Subject:

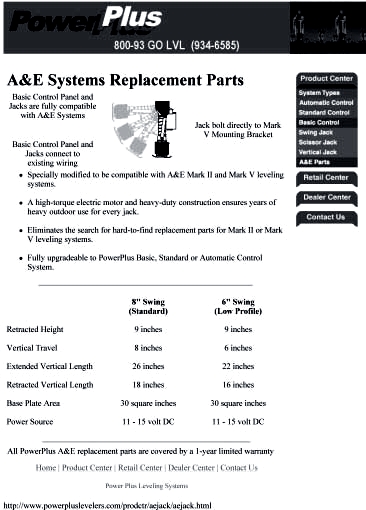

Leveling Jacks - A&E Electric

Tip:

For those needing replacements for A&E electric levelers,

check the following link:

http://www.powerpluslevelers.com/prodctr/aejack/aejack.html

or call Power Plus at 800-934-6585. They have a direct

replacement for Mark II and V leveling jacks.

#375 DeRemer

Return

to the Tip List. Return

to the Tip List.

Subject:

Hanging Wires

Tip:

Everyone should get under their coach periodically and

check for any hanging wires or wire bundles. The one

with a significant risk is the cable connecting the battery

to the generator. It may be laying over the drive shaft and

rubbing against it. Look for the broken wire ties and

replace them if necessary. Make sure you use black

wire ties. They last longer than the white ones.

#462 Wachtell

Return

to the Tip List. Return

to the Tip List.

Subject: Gas Tank, Fuel Gauge Sensor & Fuel Pump

Question:

Do you know if any of the Vironex Chassis had fuel-injected engines or if the LGS Chassis

had carbureted engines? It appears from the fuel tank shop drawings that fuel-injected

engines were first installed when the LGS Chassis was introduced. The shop drawing

dated 1-24-89 indicates a change for the LGS Chassis. J. D. Whistler, '88-1989 23' Rear Bath

Answer:

I don't know but I believe the manufacture used whatever was in stock when it built the

chassis. So when they switched from Vironex to LGS Chassis any carbureted

engines on hand were probably used; however, the majority of the LGS Chassis

have the fuel-injected

engines.

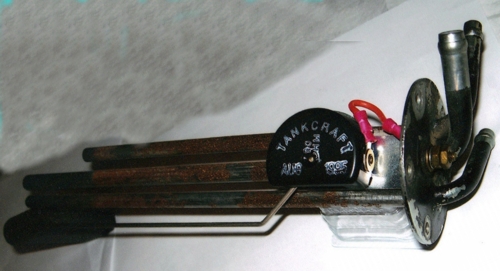

Tip: I finally found my

stuff on the gasoline tank. The tank is manufactured by the Tankcraft Corp. The

tank came ready to install.

1) Tank Part No. 3011784 came with a fuel gauge sensor for the carbureted

360 engine which has a mechanical fuel pump. In the picture above

note that the short fuel line is for the generator, the two longer ones are for the

feed to the fuel pump and the return line. They are long enough to reach

35 gallons of fuel, leaving 5 gallons to prevent any sediment from being sucked up.

2) Tank Part No. 3012040 comes with the fuel gauge sensor and electric fuel

pump mounted on it for the 360 fuel-injected engine.

Tankcraft made me a tank Part No. 3011784 in 1994. It had developed a

multitude of pin holes. I had to go through a local tank supplier to buy it. It

cost $275.00 plus $17.80 tax in 1995. I picked it up at the factory. I still have the

old tank and fuel gauge sensor. The sensor is stamped with "Tankcraft 90

OHM - 1985," but no part number.

Click here to display a high resolution

drawing of the Fuel Tank suitable for printing.

Use print preview: "Landscape" mode, "Shrink To

Fit" to print.

The tank shop drawing I have shows the tank part number on the label applied to

the right side of the tank at the fuel filling end of the tank. Another

label is applied on the fuel filling end. This is where I found the part number

on my tank but was listed as the model number. I think if you call Bevan

Kreinbring, he could tell you how to get a fuel gauge sensor at:

Tankcraft Corporation

N2900 Foundry Road

Darien, WI 53114

Telephone: +1 262 882 2500 Fax: +1 262 882 2501

http://www.tankcraftcorp.com/contact/

If I could use a computer like Tom Heald, I would send you a copy of the tank

shop drawing. Tom sure does an outstanding job as Webmaster. I'm lucky to be

able to send an E-mail.

J. D. Whistler, '88-1989 23' Rear Bath

J.D. Thanks for the drawing, picture etc. Tom

Return

to the Tip List. Return

to the Tip List.

Subject:

Fuel Tank Capacity

Tip:

If you would like to know what the capacity

of your gas tank is, measure and multiply

width by height by length (in inches) and divide by

230. That will give you total gallons. Subtract 10%

for expansion and that will give you net capacity.

Since the gas gage sensor is mounted in the middle

of the tank, the gas gage may show more or less

depending on how level your coach is at a given

moment.

Update:

You may have heard an ugly rumor how Dragi ran out of

gas on the way to Quartzsite. For the record, that is not

true. In reality, I was running an experiment to see how

much gas our tanks really hold so I could share that

information with the rest of our members.

The label on the tank shows capacity as 40 gallons.

That may be if you stand it on end but in its present

position, it holds 32 gallons. On the way back, when

the gage read 1/4 tank, I filled it up again and it took 28

gallons. In reality, I had only 1/8th of the tank left. That

tells me don’t let it get below 1/4 tank.

My sincere thanks to Wright Benson and Trish for

taking me to the gas station so I can complete this

valuable research and report the results to you.

#212 Petrovich

Return

to the Tip List. Return

to the Tip List.

Subject:

Gas Tank and Gas lines

Tip:

1990 (1988 Chassis) Gas Tank

The fuel pump (mechanical) on my

Dodge engine just wasn't working right. I

changed it out, added new fuel

filters...it was still hard to start, turning

over forever before starting.

In some cases I even started "priming the carb"

go get it going. My

driveway is on a slant, the gas lines would go dry. Why?

Finally, I

removed the gas tank. Two steel straps. Found that at the the top

of the tank

are a set of fittings, connected with rubber hose. The rubber hose

gas line

had cracked, thus the fuel pump was sucking air . I replaced the

rubber

lines.

I also cut an access hole in the floor: now I can get at the top

of the tank

where the connections are. Oh... the car no longer smells like

gas all the time

either!

George Baldwin

Return to the Tip List. Return to the Tip List.

Subject:

Gas Tank Filler Neck

Tip:

If you need to replace yours,

go to a Toyota dealer and make sure that there is an

insert for the small gas pump nozzles. This is one of the

items checked during emission test.

Return

to the Tip List. Return

to the Tip List.

Subject:

Exhaust System Wrap to cool things down

Tip:

On our 1989 Aero Cruiser I had installed a deeper transmission pan that had vents to draw air through the pan to keep oil cooler. Ran into the problem in that the right side exhaust cuts across to the left directly in front of were the cooling vents of the oil pan is located.

Went to local NAPA and purchased 15 feet of 1" exhaust wrap to cover this area.

To get the Aero Cruiser ready to work under, I first went and purchased a couple 12,000# drive up ramps to give me room to work. Chalked rear wheels and used jack stands for safety. This made it much easier to work under the coach.

I read the directions enclosed in packet and wrapped the section in front of the oil pan. 15 feet doesn't go far but did cover the cross over section. To secure the wrap I used two 2.5" stainless steel worm drive band clamps.

I told a co-worker what I did the next day and he said he had an extra 50 foot roll of 2" wrap he had gotten from Summit racing supply. I bought it from him.

That evening, with the Aero Cruiser still up on the ramps, I got under with the new roll, utility knife and two more band clamps.

Starting on the LEFT side, I unrolled about 15 feet of the roll (without cutting) and begin wrapping it around the exhaust until I had wrapped it loosely about 40 times.

Taking the end up to the bottom of the manifold, I used a band clamp to secure. Then the process of moving the wrap into position around the exhaust pipe. I used a 1" (half the width of the wrap) overlap since I had 50 feet and pulled tight as I went.

When I figured I had enough to get just past the point where the right side joins the left, I cut the wrap and finished the left side. Using a band clamp to hold temporarily.

Then to the right side following the same process. I went down to the cross over area and stopped (where I had placed the 1" x 15' section) instead of trying to do the whole length at one time. It cost me one more clamp but made it easier to deal with a shorter length of wrapping material.

Then from there to the joint area and then back to the catalytic converter, overlapping the wrap from the left side.

Project took about two hours. Results were a quieter cabin, cooler temperatures in engine compartment, starter doesn't get as hot, vented transmission pan gets cooler air.

Price of whole project under $100. Difficulty level 3 out of 10.

Rod Michaelson, '89 rear bath

Return

to the Tip List. Return

to the Tip List.

Subject:

Exhaust System Replacement Tip: If you

ever replace your exhaust system you have a chance to correct some engineering

problems with the original system. The Aero Cruiser's exhaust system is

too close to the starter motor and the transmission. As a result both suffer

heat-transfer problems because of it. Make sure the company who replaces

the system is aware of these problems.

- The pipes coming of the header needs to be a little bit longer and angled outward

to give more air

space between the starter motor and the exhaust pipe. See Tip "Starter

Overheating" for more information.

- The crossover pipe should be father away from the transmission without going

over the oil pan area.

- Leave enough room around the transmission so you can install a 4 inch deep oil pan

pan onto the transmission. See the picture on Tip on "Exhaust System Wrap to cool things down".

Even if you don't install a deeper oil pan, you want to leave the room for

cooling. It may save you a burnt out transmission.

There is plenty of room for all of this, and it should not add to the cost at

all.

Keep on Cruisin', Tom Heald

Return

to the Tip List. Return

to the Tip List.

Subject:

Catalytic Converter

Tip:

If you need to install or replace

your existing catalytic converter, it was suggested that

you are better off going to a reputable muffler shop

rather than going to the Chrysler dealer.

Kinnison

Return

to the Tip List. Return

to the Tip List.

Subject:

Generator Over-Voltage

Question:

My Generac 5200 is putting out 147 volts. Anyone know if that means a simple

replacement of an output voltage regulator? Thanks, --Frank

Answers: From several

members.

Warning: An over voltage situation can blow the circuit boards in the Refrigerator,

Air Conditioning, Microwave and anything else electronic even when these units are turned off.

So I would check the voltage with a load,

then disconnect the load and check it again (it may read higher). Just to be

on the safe side, I would adjust it without a load first (to make sure your are

adjusting it down) and then fine tune it with the load attached. If you

need a "Safe" load to adjust it, use a 100 watt bulb

So I would check the voltage with a load,

then disconnect the load and check it again (it may read higher). Just to be

on the safe side, I would adjust it without a load first (to make sure your are

adjusting it down) and then fine tune it with the load attached. If you

need a "Safe" load to adjust it, use a 100 watt bulb

or something you don't mind replacing.

or something you don't mind replacing.

Never tune the generator's engine, adjust the carburetor or "GOOSE IT" with

the coach load attached. Doing this can lead a grown man to cry,  become very agitated

become very agitated  and cost a lot of bucks!

and cost a lot of bucks!

Keep on Cruisin' Tom Heald

The Generac output voltage regulator IS adjustable. there is a screw potentiometer on the regulator body. It is located inside the generator

fuse panel and is easy to get to. That being said, there are quite a few 120V and 12V lines in there that can be grounded by a misplaced

screwdriver.

I was able to adjust mine a few times before it had to

be replaced. There are several part numbers that superseded my old

one.

Note: The regulator is mounted on the back

wall of the box that is revealed when you removed the screws holding the two

breakers. It has 4 bolts holding it to the wall. The adjuster is on the front

face.

Rick

Warning: Wrap your screw driver with 3 rounds of electrical tape. UL approved tape is

50V dielectric un-stretched. Also check the governor's operation. If it is

allowing the genny to over speed, you will get too high a

voltage.

-=Dale=-

Return

to the Tip List. Return

to the Tip List.

Subject:

Generator Fuel Line

Tip:

Inspect the fuel line going

to the carburetor. A number of them have been

found with severe cracking and gas leaking onto a

potentially hot surface. These hoses wear with

time and should be replaced.

Return

to the Tip List. Return

to the Tip List.

Subject: Generac Generator

Tip 1:

If your Generac generator fails, take a look

at the relay which seldom fails but it could. More likely

culprit may be the oil pressure switch or just low oil.

Tip 2: Here is a copy of the Diagnostic

& Repair Manual for the Generac Generator courtesy of George

Baldwin. and some pointers from Frank:

Generac Diagnostic Manual

Generac Technical Information Manual

Return

to the Tip List. Return

to the Tip List.

Subject:

Honda Generator Won't Start

Question:

I few weeks ago I was going to go out in the Aero Cruiser and thought I

would check out the systems.

The generator hadn't been run all winter so I tried to start it up.

Since the house battery was low as I cranked the generator engine the

starter started to drag and it didn't quite start but was trying.

So I put a battery charger on the house battery and plugged the coach into

the 110 Volt receptacle.

The next day after a good charge on the house battery I tried again.

It tried to start but at one point just before it started it shut down and

would not start again. I still had the coach attached to shore power and

thought that might have been the problem so I disconnected and tried again.

No luck. It will crank just fine but won't even try to start.

Any suggestions before I take it to the Honda generator repair shop?

Answer:

Suggestions from Members:

- Check oil. A low sensor will stop the genny. -=Dale=-

- Check fuel filter. All it takes is one large particle to clog such a small

filter.

-=Dale=-

- I had the same trouble, the fuel pump was working, which is evidenced by the

clicking noise of the unit. what you then have to do is prime the pump,

disconnect the tank side of the fuel filter, run a line to a gas can, or

somehow fill up the fuel filter, and see if it will start. If it indeed does,

then you know the trouble. stop generator, fill fuel filter, reconnect, and

start. This should solve the trouble. Andy

- The most popular problem with all 20-year-old generators seems to be

gas lines. Check the short one right at the carburetor for cracks. The

engine could be sucking air rather than gasoline. I am wondering if my long

line to the tank may also need to be replaced, as it is always slow firing,

even though I exercise it every two weeks. --Frank

It was the gas line! The simple fix worked this time.

Replaced the 5/16" fuel hose that was cracked through. The hose was old and as

Frank said twenty year old hoses are going to create problems.

I replaced the last 18 inches of fuel hose (hole in old hose was at the 90

degree 6 inches from the filter inlet).

Purchased 2 feet of Goodyear 5/16" fuel injection hose, 5/16" brass double barb

splice fitting, two small hose clamps, a short length of shrink tubing, and

about 24 inches of wire loom cover and some wire ties.

Took the cover off that fills the space between the door and the generator so I

could access the fuel hose from above. Cut back the hose with a good utility

knife blade back about 18 inches.

Using the heat shrink cover the area of the hose where the hose comes in at a 90

degree from the right side of the generator. I used about 4 inches of the heat

shrink to protect the hose from rubbing through like the old one had.

Install the barb fitting after installing the hose clamps on each side and push

all the way on. Tighten clamps.

Use the wire loom cover to cover the hose from the frame up to the 90 you

installed the heat shrink on.

I sucked the fuel line up to the end of the hose. (Don't try if you don't like

the taste of gasoline). Then installed the hose to the fuel filter and

tightened clamp. Make sure the fuel filter is clear. This is easy to check by

blowing through from the barbed side to the treaded side. It should have no

resistance. If it does, change the filter.

Crank engine for 10 seconds and then wait 20 seconds, then repeat. Do not over

heat the starter by cranking too long.

I used silicone spray on the old and new hoses and in the whole engine

compartment. Silicone spray is your best friend for all plastic and rubber

parts on your motorhome.

Good luck and hope if you have generator problems it is as easy to fix as this

was.

Rod Michaelson, '89 23 foot rear bath

Return

to the Tip List. Return

to the Tip List.

Subject:

Honda Generator Removal for service

Tip: The generator in my

rig is a Honda EV4010 liquid cooled generator set. I pulled the generator set the other night. It wasn't too bad. For me anyway. It does come out the hatch on the side just to let you know.

Pretty easy actually.

- Shut off the batteries at the switch in front of the coach.

- Unbolt the exhaust from the bottom. 4 bolts with a bracket.

- Remove the 3 bolts attaching the frame to the Generator base plate.

- Remove 12V DC supply line to the Generator. Located on the left side

of the generator by the start switch.

- Cut the zip ties holding to the AC seal tight conduit.

- If you have foam still attached to the bottom of the base plate, it

must be pulled loose to slide the generator out.

- Slide the generator out enough to gain clearance to the AC output

cover on the side of the generator.

- Remove AC cover and cut the white wire, pull the red wire for the

back of the switch, and release the ground by pulling the screw out of

its eyelet.

- Push the seal tight conduit under the base plate to allow clearance

to slide out the generator set.

Caution: The Honda generator set weighs over 200 lbs. So you probably will

need a partner to help or a scissor jack table to get it down to the

ground. Unless your a big guy like me. I'll need help putting it back

in though that's for sure.

- Pull out generator.

- If you have to move the coach disconnect the 12V DC at the

solenoid. Or at least tape up the end of it so it doesn't ground out.

I have pictures on my cell phone to submit to the shared knowledge data

base if its desired?

I found that the radiator has a blown core. So I'm trying to get it

fixed. Luckily its a Brass unit and is repairable. I was afraid it was

aluminum. New is $465 MSRP. The lowest I've found on the internet was $419.

Word of caution:

Change out the Radiator fluid in the gen-set if you

have the Honda and haven't done it in a while. Don't go by the hours as

a maintenance guide if its been over 5 years. If the prior owner would

have done that I wouldn't be going though all this.

I had planned on changing it myself this spring. But its too late now.

And probably too late when I bought it.

More to come. As it unravels.

Jack

Return

to the Tip List. Return

to the Tip List.

Subject:

Water Heater Gas Burner & Replacement

Tip 1:

Ralf reported that his igniter on the water heater would

not work. Closer examination revealed carbon buildup

on the electrode, which prevented the spark from

forming and igniting, the propane. Cleaning the electrode

solved the problem.

#203 Loveland

Tip 2:

Speaking of water heaters, if you have to replace

yours, try removing it from the inside before you start

removing the seal and face from the outside. Rick

reported that he was able to remove his from the

inside, which was a relatively simple task.

#101 Krafft

Return

to the Tip List. Return

to the Tip List.

Subject:

Refrigerator Gas Burner

Tip: Frank showed the

remains of his refrigerator gas burner, which had a

rusty open hole where serrations used to be. Normally,

the propane comes through the serrations at the tip of

the burner and forms a uniform wide flame. In this case

he was getting round flame that couldn’t heat the

thermal exchanger properly and the refrigerator did not

work well. Replacing the burner tube took care of the

problem.

Frank

Return

to the Tip List. Return

to the Tip List.

Subject: Keeping Gas Burners Clean and

Bug free

Tip:

We all know how much spiders love making webs in

the flame tubes of the water heater and refrigerator.

One way to discourage them from taking occupancy is

to take a small medicine bottle and punch a few holes

in the cover. Place some moth balls inside the bottle

and close it. Place one bottle in the water heater

compartment and one in the refrigerator compartment

close to the gas burners.

#212 Petrovich

Return

to the Tip List. Return

to the Tip List.

Subject: Flat Tire - How to change it

Tip:

OK, Everybody knows how to change a flat tire; you call your road service.

If you have one and they can make it in an hour or two. If not you can change it

yourself if you have planned ahead.

If you rig has levelers, use them to get the tire off the road; if not, you

have to use the 5 ton hydraulic jack that came with all Aero Cruisers.  Except, it does not have enough reach to

get the tire off the road when it is flat!

Except, it does not have enough reach to

get the tire off the road when it is flat!

First make sure you chock the other wheels with wedges or blocks of wood so

the rig won't roll when you jack it up. Next place the jack under the

frame where the springs attach and jack it up. Then place the standoffs under the

frame by the springs, reposition the jack

under the axel and take it up

the rest of the way. It is a two step process; if you don't have anything to hold the frame up

so you can reposition the jack, see the note below. I carry two aluminum Standoffs that I used to use for

a tent trailer. They are 12 inches high and have a center screw that can be raised another 8 inches or so.

I have used them twice, because it was faster and easer than waiting for a tow

truck out in the boonies.

Note: If you don't have standoffs you can

place leveling blocks under the flat tire and drive up onto them. Keep in

mind that you have to lift the flat tire about 5 inches off the ground so make

sure that somebody is outside directing you from a safe distance. Once it

is up make sure it is stable; then you

can use the jack under the axel to finish the job. Another

last-resort method is to jack it up and then place the spare-tire under the flat;

use 1.5 by 8 by 17 inch or more board or leveling-block across the rim of the

spare-tire if you have it so you

don't damage the rim. If you use the square, interlocking "Lego"

type leveling blocks, place 1 or 2 of them in the center of the rim. Then lower the rig

onto the spare-tire to reposition the jack. However,

these methods are not nearly as

safe as using standoffs.

Also see

Old Tires can KILL you!,

Flat Tire? Use the Air Bag Compressor to fill it up and

Spare Tire - Lowering and Raising.

Keep on Cruisin', Tom Heald

Return

to the Tip List. Return

to the Tip List.

Subject: Spare Tire - Lowering and Raising

Tip: There are two different

systems used on the Aero Cruiser: an Electric Power Lift or a Manual crank. Your

rig will have one or the other, not both.

If your spare tire has a "Electric Power Lift"

and you have no idea where the switch is that

operates it, look inside the sewer access door. The switch is hard to find

so look around. Keep in mind that the ignition switch must to be in the accessory mode to operate it.

It is located here so you can watch the tire as you raise it. Stop raising

the tire when it is just snug with the frame. If you over do it you may

burn the switch out. (See Update below)

If your spare tire has a "Manual Lift" it

cranks down using the lug-wrench for your wheels. The end of the shaft is located

by the trailer hitch in the rear of the rig. Just look for the bolt head

and crank it down or back up when you are done.

In either case don't forget to give any bearing points a few squirts of oil from

time to time.

Also see

Old Tires can KILL you!,

Flat Tire? Use the Air Bag Compressor to fill it up and

Flat Tire - How to change it.

Keep on Cruisin', Tom Heald

Update on the Switch:

Changed my switch to lower and raise the spare last night. This switch

(which is located behind the dump valve door, if equipped) is only activated with

the ignition switch on.

My switch worked letting the tire down but not

back up. This is a heavy duty three position switch. Momentary on (up) center

(off) momentary on (down) with six spade terminals. Cole Hersee part #

55065-03.

The momentary on (up) contacts were fried and the reason would

be that all the current to drive the spare tire raise and lower motor goes

through this small switch. This pulls a large amount of amps in the up position.

When someone raised the tire before, they held the switch in the up position too

long and over heated the contacts in the switch.

To save the switch, lift

the tire with the switch for 5 seconds, wait 10 seconds, then 5 seconds again,

and wait again. Keep doing this until tire is just secure against the frame but

no more.

Happy trails, Rod Michaelson

Return

to the Tip List. Return

to the Tip List.

Subject:

Fresh-Water Gauge Subject:

Fresh-Water Gauge

Tip:

Our digital tank gauges leave something to be desired. When only the bottom light (of 4) is lit, we might have as much as 1/3rd or 1/4th tank of fresh water, or we might have little or none left. If your fresh-water tank is visible, you can shine a light into it and see the water level. However, my tank is enclosed in walls, so I cannot see it. So, I decided to add a visual

gauge next to the tank. I bought a tee to go in the line from the bottom of the tank to the water pump, an elbow, a 2-foot length of clear hose, and a plastic valve, all for less than $10. I ran the hose up one edge of the tank enclosure, all the way to the ceiling of the storage area (that supports our bed). Thus, the hose fills with water to the same level as the tank –– when the valve is open. The valve must be closed to be sure no water goes into the storage area if I get the tank too full, and to be sure the pump does not suck the water out of the

gauge and then suck air rather than water. The valve must be open for a couple of seconds to allow the water level in the

gauge to equalize with that in the tank. A white blind behind the hose makes the water in the tube very visible.

Another view of the gauge can be seen on the left side of the last picture in Water

Pump Tip below

Frank

DeRemer

Return

to the Tip List. Return

to the Tip List.

Subject:

Water Pump Replacement 1

Tip:

The old water pump was a Shurflo unit from June 1988. The pump would never turn

off unless you turned off switch above the stove in the kitchen area. Tip:

The old water pump was a Shurflo unit from June 1988. The pump would never turn

off unless you turned off switch above the stove in the kitchen area.

Changed

to a new Flojet automatic multi fixture pump model 4406-143 type IV. Purchased

from JC Whitney for a little over $80.

Now the pump only turns on upon

demand and shuts off immediately when the demand is turned off. 35psi and 3.2gpm

will give a good shower.

The

pump in a rear bath model fits under the closet. [On other models the pump

is under the bed next to the water tank.] The old pump had the motor

below the pump. Flojet says to place motor above the pump. To do this on the

Aero Cruiser the four bolts that hold the pump to the motor have to be pulled out

and the pump turned 180 degrees to get the flow going the correct direction.

Scale of 1 to 10 with 1 being easiest, this is a 2.

Happy trails

Rod Michaelson Note:

On my 1990 Rear Bath model the pumps is located under the bed next to the water

tank and darn hard to get to, so I cut a trap door in the bed platform -- with

appropriate bracing etc -- to get easy access to it and the pluming around

it. See "Water System, access under Shower, Bed & Pump"

for more information.

Keep on Cruisin', Tom Heald

Return

to the Tip List. Return

to the Tip List.

Subject:

Water Pump Replacement 2

Tip:

I found a used SHURflo SmartSensor water pump on eBay for a good price, so I decided to upgrade. This

pump has a microprocessor that senses the slightest reduction in pressure and runs the pump only as fast

as needed to keep the pressure up, rather than waiting until the pressure is below a threshold and hammering

away to get it back up. This pump also has five chambers instead of three; it pushes 5.7 GPM rather than

the 2.8

Tip:

I found a used SHURflo SmartSensor water pump on eBay for a good price, so I decided to upgrade. This

pump has a microprocessor that senses the slightest reduction in pressure and runs the pump only as fast

as needed to keep the pressure up, rather than waiting until the pressure is below a threshold and hammering

away to get it back up. This pump also has five chambers instead of three; it pushes 5.7 GPM rather than

the 2.8

of the old pump. All that means a smoother, quieter delivery of more water “just like home”. Regular

price at Camping World is $233.33; I got a five-year-old for $33.00.

of the old pump. All that means a smoother, quieter delivery of more water “just like home”. Regular

price at Camping World is $233.33; I got a five-year-old for $33.00.

Pictured in the middle is the old pump as

installed by the prior owner of my rig. Note that my system had an

accumulator

tank that smoothes out the operation of the pump: it flows longer

between pumps. Notice also that all the tubing is rigid. That transmits the

vibrations from the pump to everything around it. The installation instructions

say to use flexible hose for 18 inches on each side to reduce that effect. (That

improvement you can make for about $3 worth of hose.)

tank that smoothes out the operation of the pump: it flows longer

between pumps. Notice also that all the tubing is rigid. That transmits the

vibrations from the pump to everything around it. The installation instructions

say to use flexible hose for 18 inches on each side to reduce that effect. (That

improvement you can make for about $3 worth of hose.)

I made that improvement when I installed the new pump, as you can see next. Notice that I also

added a recommended strainer to prevent any debris that gets into the fresh water tank from

getting into the pump. I also added a

Fresh-Water Gauge which can be seen on the left side of the last picture and

is described in a separate tip. I plan to update this article with a report of how it works, after

I get some real experience with it.

Frank

DeRemer

Return

to the Tip List. Return

to the Tip List.

Subject: Recycling Grey Water

Tip:

Having upgraded my fresh-water pump to a SmartSensor, I used the old water pump for an experiment, which,

if successful, will extend my dry-camping ability. I reasoned that it was a waste of fresh water to flush

it down the toilet. Why not use grey water instead? That would both make my fresh water last longer and

move some grey water into the black tank with each flush, thus making the grey tank last longer too. Furthermore,

if the grey tank gets full and

Tip:

Having upgraded my fresh-water pump to a SmartSensor, I used the old water pump for an experiment, which,

if successful, will extend my dry-camping ability. I reasoned that it was a waste of fresh water to flush

it down the toilet. Why not use grey water instead? That would both make my fresh water last longer and

move some grey water into the black tank with each flush, thus making the grey tank last longer too. Furthermore,

if the grey tank gets full and

the black is not, which is usual for us, I could just do a continuous flush

for a while to move more grey water into the black tank. It sounds like a win-win-win (fresh, grey, black). But

will we like even a little grey water sitting in the toilet?

the black is not, which is usual for us, I could just do a continuous flush

for a while to move more grey water into the black tank. It sounds like a win-win-win (fresh, grey, black). But

will we like even a little grey water sitting in the toilet?

I bought (1) a tee to put in the drain line of the grey tank, before the dump valve, (2) a strainer to

prevent any

prevent any

debris in the grey tank from getting into the pump, (3) a flexible hose to go to the pump

and another (not shown above) to go to the toilet, and (4) the needed hose connectors. I mounted the

pump (and the accumulator tank) under the floor between the tanks. I ran a line to the toilet (difficult

to access), capped off the old supply line, and connected the toilet to the new line.

I cut out a 1-inch section of the grey dump line, removed the valve, glued in the tee, and replaced

the dump valve. The picture

the dump valve. The picture

on the right shows that the strainer is accessible for cleaning and

replacement, just inside the small, contoured door above the dump valve.

Now, when I dump the tanks, I must clean the strainer and put a little fresh water in the grey tank

for the first flush or two –– say, one gallon. I also plan to add enzymes to eat the emoluents; with

every flush, they will be moved to the black tank where they are needed even more. After our first

shower, we will have plenty of grey water for flushes. We will also have to be careful not to put

coffee grounds and the like in the kitchen sink, but we have been doing that anyway. I hope, by fall

of 2010, to tell you how the system works.

Frank

DeRemer

Update: I have

now been on a seven-day trip by myself and a five-day trip with Lynda. I

am very happy with the gray-water-recycling set-up. I was surprised at how

much fresh water it saves and how low it keeps the gray tank. After seven

days I still had half a tank of fresh water, and the gray water tank never

showed more than one quarter full. With both of us for five days, we used

about 3/4 of the fresh and had about 1/2 gray at the end. I find the

toilet actually stays cleaner and is easier to swish out, as it always has

slightly soapy water in it -- a surprising side benefit. It was a

noticeable improvement over last year's experience during our 40-day trip.

Frank

DeRemer

Return

to the Tip List. Return

to the Tip List.

|

Copyright© 1999-2016

Freelance Ink.

All Rights Reserved.

|

|

|